- 040-27819777, 9848306302

- info@apexplosives.com

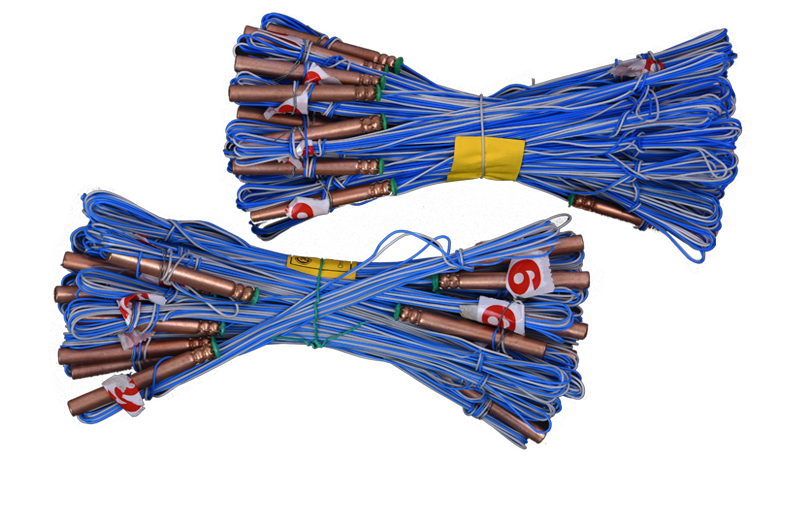

Copper Electric Detonators/ Copper Coated Steel Electric Detonators comprise copper shells filled with PETN and ASA as base and primary charge respectively. These shells are crimped with a pair of PVC coated wires soldered to fuse heads. The two lead wires are passed through PVC plugs of required length and diameter to protect from moisture and water. The other end of the wire is shorted to the detonator to protect against any stray/static current.

CEDs are used for initiation of explosive charges with controlled blasting which are used in underground gassy coal mines. CEDs are arranged in series. The firing is carried out by using an exploder which gives the required energy in the form of an electric impulse.

| Shell Material | Copper/ Copper Coated Steel |

| Shell Length | 43mm |

| Base Charge | PETN |

| Primary Charge | ASA |

| Lead wire colour | white/white |

| Lead wire material | Tinner steel |

| Bare Wire | 0.46+/- 0.02 mm) |

| Lead wire resistance | 0.7 ohms/meter |

| Standard lengths | 1.8, 2.0, 2.2, 2.5 or as per requirement |

| Fuse head characteristics: Fuse head resistance | 1.6 to 2.4 ohms |

| Firing impulse | 3.2 mws/ohm |

| Series firing | 1.2 amps DC |

| No fire current | 0.18 amps applied for 300 seconds |

| Packing material | Corrugated box |

| Quantity per packet | 50 nos. |

| Quantity per box | as per length of wire |

25 detonators are crimped and formed into a bundle. Two such bundles are wrapped in craft paper to make a packet of 50 nos. As per the length of the wire, the packets are kept in a corrugated box.

| Class | 6 |

| Division | 3 |